How to Convert Sea Water into Fresh Water

As the world’s population grows and climate change brings more wildfires and drought, clean water is becoming an increasingly precious resource.

According to the UN report in 2019, nearly half of the world's population (about 3.6 billion) live in areas potentially short of water for at least one month each year. If proper measures are not taken, this number will rise to 4.8 to 5.7 billion by 2050. To solve the shortage of water resources, there is a seemingly very simple method- converting sea water into fresh water. The challenge is to do it on a large scale using low cost, sustainable methods.

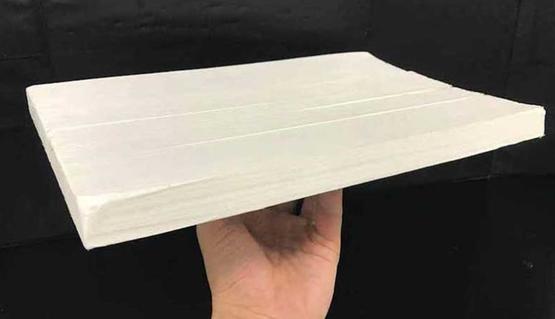

Researchers at the University of Colorado at Boulder and the University of Maryland believe wood could be the answer. They used wood to make an ultra-thin filter membrane to desalinate and purify water. According to a report on this research by Science Advances, this 0.5 mm membrane may become a sustainable alternative to the petroleum-derived plastic membranes widely used in desalination plants.

Traditional Desalination Methods

In fact, some water-scarce areas have successfully obtained clean, drinkable fresh water from seawater. In regions such as the Middle East and California, desalination plants are already supplying water for residents. Most rely on the reverse osmosis process, in which seawater is forced into porous membranes and filtered to remove salt and impurities. However, this method not only consumes huge energy, but also consumes expensive plastic filter membranes, which are also very prone to clogging, leading to greater costs.

At that moment, membrane distillation technology , a seawater desalination technology that has not yet been commercialized , has attracted attention due to its energy-saving and environmentally-friendly characteristics and has entered people's field of vision. The so-called "membrane distillation" is the use of solar energy to evaporate seawater, and the water vapor is filtered through a hydrophobic membrane, and then condensed to become clean fresh water. However, the hydrophobic membrane used in this treatment is made of polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), polypropylene (PP) and other high polymers based on the petroleum industry. On the one hand, these materials are not suitable for efficient heat preservation, on the other hand, they are difficult to degrade and easily cause environmental problems. Therefore, limited by cost and energy consumption, this technology cannot be widely used.

Sustainable Low Energy Consumption Nano Wood Membrane

The research team decided to use sustainable, lower-cost materials to make the distillation membrane, and finally selected American basswood . The production process is as follows:

Cut the wood chips into 2 mm thick and boil them in boiling water for 12 hours;

Rinse three times with hot distilled water to remove impurities on the wood chips;

Put the wood chips into the boiled bleach solution until the wood turns white to remove the lignin;

The lignin-removing wood chips are washed and dried in cold water to preserve their nano-porous structure. Eventually, they came up with a colorless, ultralight-like styrofoam material. The material can also be used for insulation and cooling.

Nevertheless, wood itself has strong hydrophilicity, which is obviously not suitable for use as a seawater filtration membrane. Therefore, the researchers intend to use silane to chemically react with the abundant hydroxyl functional groups on the surface of the material to change the hydrophilicity of the wooden surface and make the material hydrophobic. At the same time, the arrangement of cellulose fibers is retained, allowing heat to be conducted along the surface of the material, but the holes formed between the fibers make it impossible for heat to penetrate the material.

The researchers heated one side of the filter membrane made of this material so that the water flowing through the side of the membrane would quickly evaporate. It takes much less energy to make water vapor in this way than it does to boil water to make water vapor. In addition, this kind of film has more holes than commercial plastic films, making water vapor more permeable.

However, each square meter of membrane can only filter about 20 kilograms of water per hour, which is about half the efficiency of commercial plastic membranes. Overall, it is not as effective as expected.

The problem, the team wrote after investigating, is that the resulting film is thicker and has smaller pores than expected. Changing to other wood with better pore size and making a thinner membrane should solve this problem. They also plan to make membranes that are more durable under high temperature and harsh chemical conditions.

Water shortage is a major problem worldwide. Desalination of seawater is an important solution for mankind to solve this problem. In order to achieve this goal, people need to constantly find better ways. Although the current experimental results are still not satisfactory, the researchers are full of confidence. It is hoped that in the near future, nano-wood membranes are expected to replace plastic filter membranes, desalinating seawater more efficiently and environmentally, for the benefit of mankind.

OTHER NEWS

-

- The more generous the society is, the longer its members live

- By Michelle 24 Apr,2023

-

- Can you get night vision by eating carrots?

- By Jessica 24 Apr,2023

-

- How to Download and Install Wyze App for Free?

- By Gray 24 Apr,2023

-

- Ten Trends of Social Media

- By Clarence 24 Apr,2023

-

- Fitness Video Apps: The New Trend

- By Mary 24 Apr,2023

-

- Alan Turing: Stolen Relics to be Returned After 36 Years

- By Jose 24 Apr,2023

-

- Why is space vacuumed?

- By Christina 24 Apr,2023

-

- Argentina Mourned Over Maradona’s Death for Three Days, Why a Football Player Could Own Such an Honor? (II)

- By Moore 24 Apr,2023

-

- Abandoned orange cat waving to passersby

- By Maria 24 Apr,2023

-

- The upcoming asteroid is closer than the moon

- By Wanda 24 Apr,2023

-

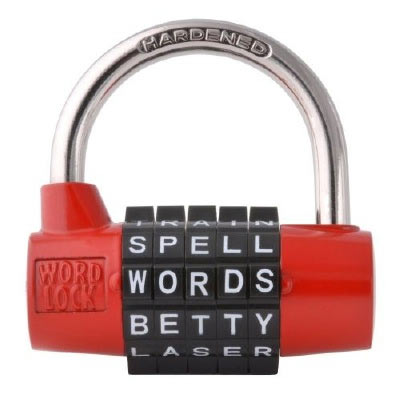

- How can we set and remember easy-to-remember but hard-to-guess passwords?

- By Katherine 24 Apr,2023

-

- The Weakening Earth‘s Magnetic Field

- By Rose 24 Apr,2023

1

1 1

1